Physically cross-linked polyethylene foam is a fascinating material that owes its unique properties to its molecular structure. Imagine a complex network of polymer chains intertwined like a spider’s web, strengthened by cross-linking bonds that act as glue holding everything together. This molecular arrangement is the secret behind the foam’s exceptional durability, flexibility, and thermal insulation capabilities.

When it comes to the manufacturing process of physically cross-linked polyethylene foam, precision is key. Through the use of chemical agents or irradiation, the polymer chains are strategically bonded together, creating a robust material that can withstand the test of time. It’s like crafting a masterpiece where every detail matters, ensuring that the foam meets the highest standards of quality and performance.

The applications of physically cross-linked polyethylene foam are as diverse as they are impressive. From providing insulation in automotive parts to cushioning delicate electronics during shipping, this versatile material has found its way into various industries. Its water resistance and shock absorption capabilities make it a top choice for applications where reliability is paramount.

In conclusion, physically cross-linked polyethylene foam is not just a material; it’s a marvel of science and engineering. Its molecular structure, manufacturing process, and wide range of applications showcase the endless possibilities that can arise when innovation meets functionality. Whether you need to protect, insulate, or cushion, this foam has got you covered with its exceptional properties and performance.

Molecular Structure of Polyethylene Foam

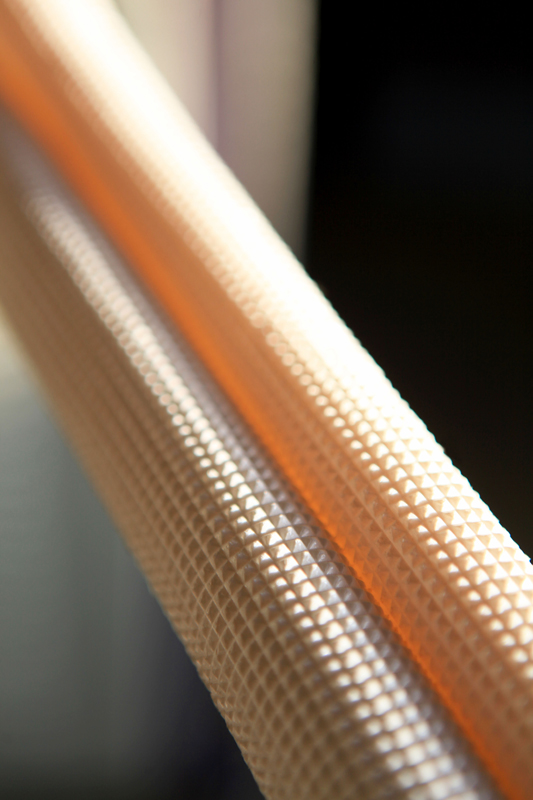

The molecular structure of physically cross-linked polyethylene foam is a fascinating aspect that contributes to its unique properties and versatility. In this type of foam, the polymer chains are interconnected through physical bonds, creating a three-dimensional network that enhances the material’s strength and resilience. These cross-linking bonds act as molecular bridges between the polymer chains, providing stability and preventing the material from collapsing under pressure.

Imagine the molecular structure of polyethylene foam as a complex web of interconnected chains, each strand reinforcing the overall integrity of the material. This intricate network allows the foam to withstand external forces and maintain its shape, making it ideal for applications requiring durability and impact resistance.

One of the key characteristics of physically cross-linked polyethylene foam is its flexibility, which is directly influenced by the arrangement of polymer chains within the material. The ability of the chains to move and adjust their position contributes to the foam’s pliability, allowing it to conform to different shapes and contours. This flexibility makes polyethylene foam an excellent choice for packaging materials that need to adapt to various product shapes and sizes.

Additionally, the molecular structure of polyethylene foam plays a crucial role in its thermal insulation properties. The trapped air pockets within the foam structure create a barrier against heat transfer, effectively insulating the material and maintaining temperature stability. This thermal resistance makes polyethylene foam an ideal choice for applications requiring insulation, such as HVAC systems and cold chain packaging.

Manufacturing Process of Cross-Linked Polyethylene Foam

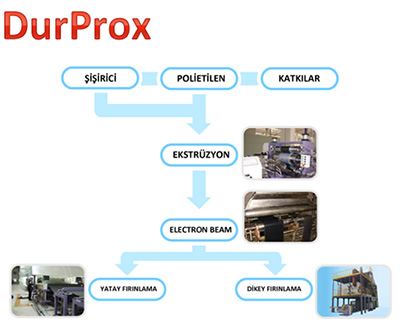

When it comes to the manufacturing process of physically cross-linked polyethylene foam, it involves intricate steps that transform raw materials into a versatile material with exceptional properties. The process begins with the selection of high-quality polyethylene resin, which serves as the foundation for the foam’s structure.

One of the primary methods used in creating cross-linked polyethylene foam is through a chemical cross-linking process. This process typically involves the addition of cross-linking agents, such as peroxides, to the polyethylene resin. These agents facilitate the formation of cross-links between polymer chains, enhancing the material’s strength and durability.

Alternatively, another common method for manufacturing cross-linked polyethylene foam is through irradiation. In this process, the polyethylene resin is exposed to high-energy radiation, which induces cross-linking between the polymer chains. This method is known for its efficiency and ability to produce foam with consistent properties.

During the manufacturing process, the polyethylene resin is typically mixed with other additives, such as blowing agents, to control the foam’s density and cell structure. The mixture is then heated and extruded through a specialized die to form the desired shape and thickness of the foam.

After the foam is extruded, it undergoes a curing process to allow the cross-linking reactions to fully develop, ensuring the material achieves its optimal properties. This curing process may involve exposure to heat or additional chemical treatments to stabilize the foam’s structure.

Overall, the manufacturing process of physically cross-linked polyethylene foam combines precision, innovation, and expertise to produce a material that excels in insulation, packaging, and cushioning applications across various industries.

Applications and Benefits of Cross-Linked Polyethylene Foam

Physically cross-linked polyethylene foam finds a wide range of applications across various industries, thanks to its exceptional properties and benefits. One of the primary uses of this versatile material is in the automotive sector, where it is utilized for insulation, gasketing, and sealing applications. The foam’s ability to provide thermal and acoustic insulation makes it an ideal choice for reducing noise and maintaining optimal temperatures within vehicles.

In the construction industry, physically cross-linked polyethylene foam is valued for its cushioning and impact resistance properties. It is commonly employed as underlayment for flooring, helping to reduce noise transmission and provide added comfort underfoot. Additionally, the foam’s moisture resistance makes it suitable for use in damp environments, such as basements or crawl spaces.

Sports equipment manufacturers also benefit from the use of cross-linked polyethylene foam due to its lightweight nature and shock-absorbing capabilities. From helmet padding to protective gear, the foam provides a comfortable and protective layer that helps reduce the risk of injury during physical activities.

Furthermore, the water-resistant properties of physically cross-linked polyethylene foam make it an excellent choice for marine applications. Whether used as flotation devices or boat fenders, the foam’s buoyancy and durability ensure reliable performance in aquatic environments.

Overall, the benefits of physically cross-linked polyethylene foam extend beyond its specific applications, offering a cost-effective and environmentally friendly solution for various industries. Its versatility, durability, and protective qualities make it a go-to material for insulation, packaging, cushioning, and more, demonstrating its value across different sectors.

As we come to the end of our article, do not forget to review the following pages of Durfoam: